One of the things I learned is that the stock gearbox on the TR5T is somewhere between wide ratio and standard. The classic/cool thing to do would be to source a close ratio gearbox. This would be the gearbox run back in the late 60s at Daytona when the Triumph 500 was a bike to beat. The problem is the difference in the races being run. The first gear on a close ratio is too high for a speedy start that is so key to getting yourself out front for a short race. A longer race, like Daytona, gave you enough miles to make up for a slow start. The low 1st gear in the bike gave me some goods starts that the bike and rider were not up to task for.

Tracks like New Jersey Motorsports Park have a lot of twists and carousels that will keep you between 2nd and 3rd more than you would expect. My experience for the Triumph was that the distance between 2nd and 3rd was too great and that it left me at a great disadvantage.

The ratio for 4th stays the same Between the different wide, standard and close ratios. It was hard to see a considerable change in 3rd from the TR5T and standard gearbox, as well. The plan is to keep all other gears, but update 2nd to standard specs.

Part of getting into the gear cluster requires tearing down of the clutch. This is where I should mention that prior to racing I never saw the bike run for more than a couple seconds. It turns out that the clutch decided not to work on race day and I had to jam another friction plate in there to get anything to happen. The truth is that I had planned on rebuilding the clutch beforehand, but the parts never arrived in time. New clutch springs and friction plates await installation.

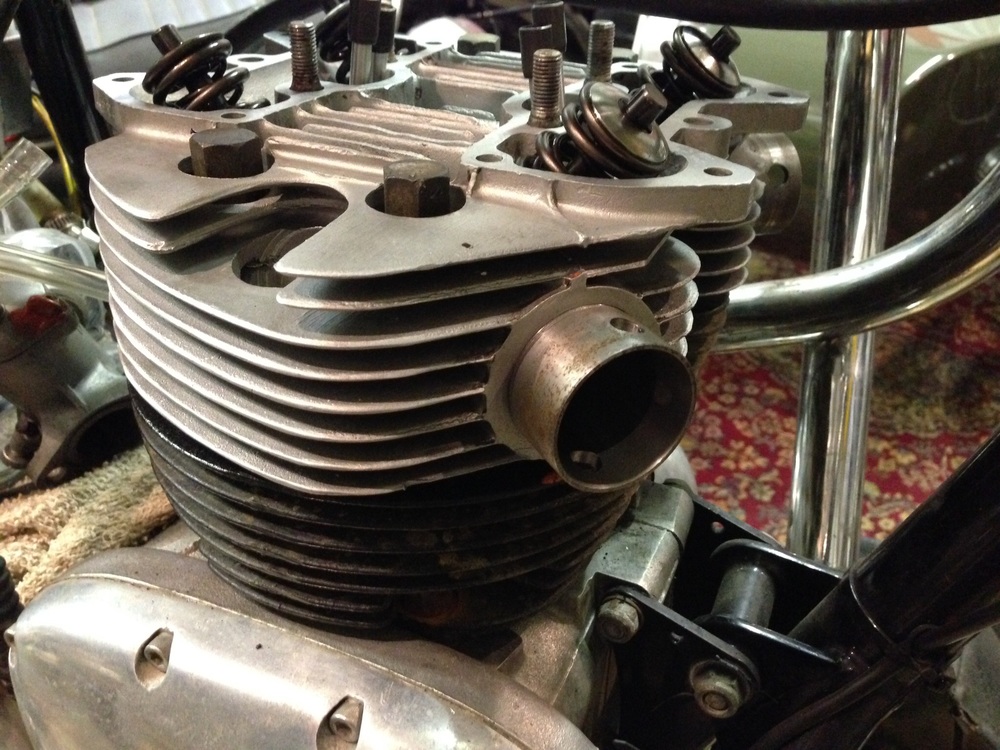

The head all ready to go with new valves and spigots.

Getting myself and the Triumph on the track last season was an incredible experience. Starting to assemble the bike less than two weeks before racing was something I wanted to avoid the next time. If plans have gone, as planned, the bike would be done by now and already tested. As it stands, Roebling is about 4 weeks away and I am just starting to get to work on the bike.

There only thing I got done right away to the bike was putting proper exhaust spigots in. For some odd reason on the TR5T Triumph decided to use push in exhaust pipes unlike every other T100 engine. Last year at the track, I returned to the pit with a pipe dangling off the side. Many thanks to John Melniczuk for bailing me out that day and Tom Healy for getting the heads tapped for the spigots.

This engine was run as I got it. I have no clue what is really inside. My understanding is that it was raced on some local TT tracks. Having to remove the head to get the spigots in revealed some oddities. Stock valve guides were in the intake and some mismatched oversized guides were in the exhaust. Replacement guides and valves all around. For some reason I had been running lightened racing springs in my everyday T100 and those have been 'borrowed' permanently to complete the head. It also appears that whoever did the engine before me was using an earlier copper gasket that is thicker than the proper one (let's hope there was not a good reason).

I should be buttoning up the top end today and then will get on the gearbox and clutch next week.

Luca Cipolla is a four and two wheel moto addict going to school for film. A nasty incident with a car not noticing his bike put him out for more than a semester last year, but his love of two wheels lives on in this short film.

Unlike some hipster homage to grooming and pseudo manliness here is a simple vignette of a real person with their actual bike just getting as much out of a day as he can.

Last week I just finished up the custom wiring for a customer's Triumph. The bike is a 1963 TR6ss that came to him as a basket case in 1971. It came to me when something crazy went on with the wiring.

Along with a custom harness a new digital ignition was installed. This allowed us to swap things around and make the bike a negative ground system as per the owners request.

Early on the single carb TR6 was changed into a twin carb along with the standard 650 jugs being replaced with an oversized 750cc set. A belt drive and dry clutch is also hidden below the primary cover. As this bike is done for the guy riding it and not for anyone else, it contains a mix of styles that make it unique. Along with a mix of cafe and bobber elements, two of my favorite unique/interesting elements of the bike are the large tank and the Aermacchi front end. The owner says the front brake could be better (after some test riding, I agree), but at the time it was an easy way to get a set of Ceriani forks. The meager front brake has stayed on during the search for something better. TT pipes along with a bobber style seat, a custom oil tank, and pillion pad complete the look.

This bike is a good example of a personal project that will morph and change over time. It may send the critics into a tizzy over certain elements, but the performance of this bike is real and the ride is quality.